Static electricity is a part of everyday life. From the slight shock received on a door knob after walking along a carpet-covered floor to shocking someone's hand while wearing a thick sweater, static electricity is a simply an element of daily interactions that many choose to ignore. However, in high-risk environments like the automotive or medical manufacturing industries, any exposure to static can be destructive during the production processes.

One common form of static generation, tribocharging, is what occurs when two materials or substances come into contact and then are separated. This is the type of static generated from removing plastic packaging, getting out of a vehicle or walking across a rug. It is the break in contact that ultimately causes the charge.

Meanwhile, electrostatic induction occurs when an electrically charged object or device comes into contact with a conductive object without being grounded. An electrostatic field forms as a result of the charged object, causing the other object's charge to redistribute. Thus, whenever a metallic substance enters the newly formed conductive pathway, a static shock is likely to occur.

Manufacturers that produce electronics or other products that could be harmed by the presence of an electrostatic discharge set up ESD Protected Areas to minimize or eliminate the generation or retention of ESD. The production categories that must be addressed in this process include the environment, the tools, the clothing and the products.

"Clothing is another catalyst for ESD in the manufacturing process."

A variety of internal and external environmental factors contribute to the degree of static electricity that is present during a manufacturing process. High levels of humidity, for example, impedes the risk of static charges, which is humidifiers are helpful for use on dry days, where static could otherwise be more prevalent. Static dissipative flooring, such as various types of tiling, concrete or even carpet, is often used to impede the flow of electrical current as well.

Clothing is another catalyst for ESD in the manufacturing process. Most normal clothing carries and creates static, which is dangerous in an ESD Protected Area. This is why worker must wear ESD approved shoes, clothing and coats.

"With an ESD coat covering all clothing, it will tend to dissipate any static that might otherwise reach any electronics equipment. It may also provide a form of shield against any induced static," Radio-Electronics, an online resource for electrical engineers, explained on its website. "With many clothes made from man-made fibres, high levels of static can build up. Ties worn by men are a very good example. Often being made from man made fibres very high levels of static can be carried by them, and they can easily reach sensitive electronics equipment when being worked upon at a bench."

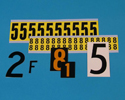

At Stranco, we offer a variety of thermal transfer labels for a wide range of labeling applications, including label stocks with low electrostatic discharge properties. Companies operating in static-free environments should consider our low ESD polyester and polyimide thermal transfer label stocks, which will help keep your electronic devices safe from static discharge during the manufacturing and production process.

Contact us today to learn more about our wide selection of labeling solutions.